Target Material Technology: A Comprehensive Analysis from Fundamental Principles to Cutting-Edge Applications

Release time:

2025-06-11

As the core material in Physical Vapor Deposition (PVD) technology, the target material essentially serves as a "material source" where atomic-level material transfer is achieved through high-energy particle bombardment. In the sputtering process, the target material acts as the target for high-energy ions (such as argon ions). When ions bombard the target surface with energy of 3-5 keV, the target atoms gain sufficient kinetic energy to escape the lattice, migrating to the substrate in the gas phase and depositing as a film.

I. Core Concepts and Mechanisms of Target Materials

1. Essential Definition and Functional Positioning of Target Materials

2. Physical Basis of Sputtering Process

(1) Four-Stage Model of the Sputtering Process

- Gas Ionization Argon gas is introduced into the vacuum chamber and a high-frequency electric field (13.56MHz) is applied. Argon atoms are ionized into Ar⁺ ions and free electrons, forming plasma;

- Ion Acceleration Under the action of the electric field, Ar⁺ gains kinetic energy and bombards the target material surface with energy of 200-1000eV;

- Atom Ejection Target material atoms obtain sufficient energy through "cascade collisions" to overcome lattice constraints and form sputtered particles (90% neutral atoms, 10% ions);

- Film Deposition Sputtered particles migrate to the substrate at a speed of 300-1000m/s, forming a dense film through surface diffusion and atomic rearrangement.

(2) Mechanism of Target Material's Influence on Film Properties

- Chemical Matching The ratio of indium to tin atoms in ITO (Indium Tin Oxide) target material must be strictly controlled at 9:1. A deviation exceeding ±0.5% will cause the sheet resistance of the film to increase by 20%, affecting the touch sensitivity of the touch screen;

- Microstructure Consistency The grain size of the target material needs to be controlled at 5-10μm and the orientation needs to be uniform; otherwise, anisotropy during sputtering will cause the film thickness deviation to exceed ±3%;

- Thermal Stability The temperature of tantalum targets used in semiconductors can reach 300℃ during sputtering. Hot isostatic pressing (HIP) treatment is required to eliminate internal stress and avoid cracking of the target material due to inconsistent thermal expansion coefficients.

3. Performance Evaluation System of Target Materials

| Index Category | Semiconductor Grade Requirements | Display Panel Grade Requirements | Photovoltaic Grade Requirements |

| Purity | ≥5N (metal impurities <1ppm) | ≥4N (metal impurities <10ppm) | ≥3N (metal impurities <50ppm) |

| Density | ≥99.5% theoretical density | ≥98% theoretical density | ≥95% theoretical density |

| Impurity Distribution | Uniformity <5ppm spatial fluctuation | Uniformity <20ppm spatial fluctuation | Uniformity <50ppm spatial fluctuation |

| Grain Size | 5-15μm (single crystal target material <1μm) | 10-30μm | 20-50μm |

II. Classification System and Characteristic Comparison of Target Materials

1. Fine Classification by Material Composition

(1) Metal Target Materials: The "Conductive Foundation" of the Electronics Industry

- High-purity Aluminum Target (Purity ≥5N): Used for the first layer of metal wiring in semiconductor chips, requiring iron and silicon impurities <5ppm; otherwise, Al-Fe-Si precipitates will form, reducing the electromigration resistance of the wiring by 50%. In TSMC's 7nm process, high-purity aluminum targets with grain sizes <5μm are used to increase the electromigration lifetime of the copper interconnect layer to over 1000 hours.

- Titanium Tungsten Alloy Target (Ti:W=7:3): As a barrier layer material, the oxygen content needs to be controlled <200ppm; otherwise, TiO₂ impurities will cause the barrier layer resistance to increase by 30%, affecting chip reliability.

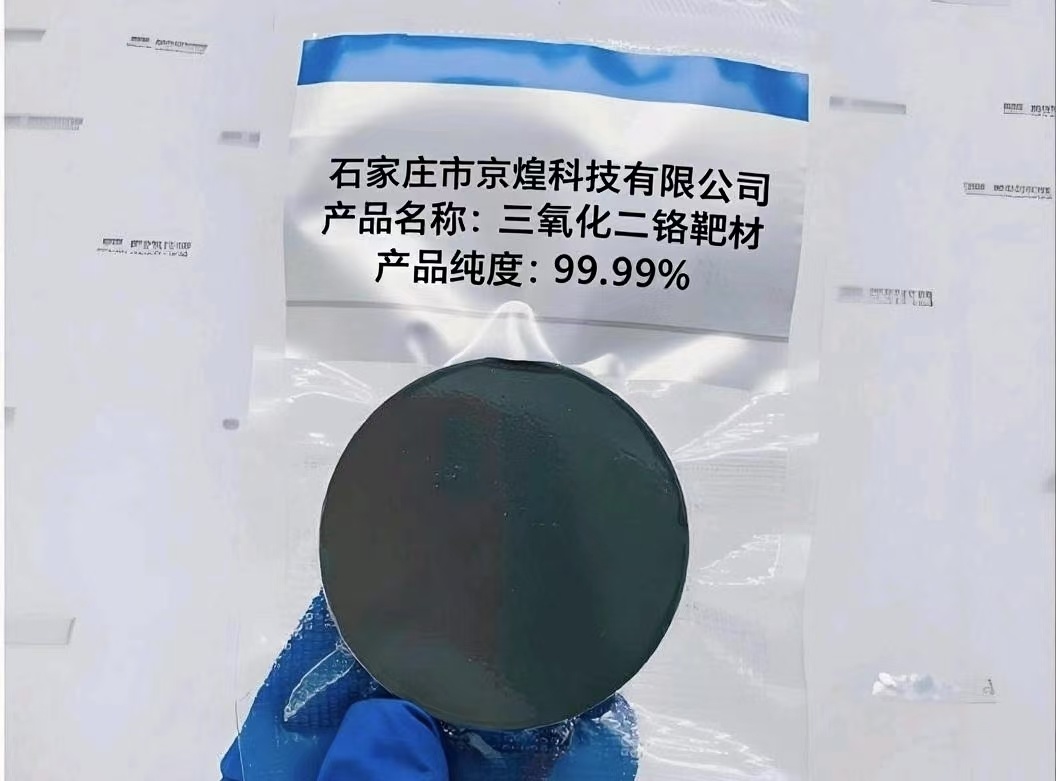

(2) Ceramic Target Materials: "Functional Carriers" in the Optoelectronic Field

- ITO Target Material (In₂O₃:SnO₂=9:1): Key indicators include:

- Resistivity <1.5×10⁻⁴Ω·cm (ensuring touch screen response speed <5ms);

- Visible light transmittance >85% (400-700nm band);

- Particle size <0.5μm (avoiding film surface roughness >1nm).

BOE's 10.5-generation line uses G8.5 size ITO targets, which require hot isostatic pressing (HIP) treatment to achieve a density of 99.8% to ensure that the resistance uniformity deviation of large-area display panels is <5%.

(3) Composite target materials: An "integrated solution" with multi-dimensional performance

- CIGS (copper indium gallium selenide) target materials Through gradient composition design (Cu/(In+Ga)=0.85-0.95, Ga/(In+Ga)=0.2-0.3), the photoelectric conversion efficiency of thin-film solar cells exceeds 23%. Würth Solar in Germany uses a three-layer structure (Cu-In/Ga-Se) for its CIGS target materials, achieving atomic-level compositional uniformity control through simultaneous magnetron sputtering deposition.

2. In-depth analysis by application scenario

(1) Semiconductor manufacturing: "Material engraving" with nanometer-level precision

(2) Display panels: The "ultimate challenge" of large-area uniformity

- Purity ≥5N (Ag≥99.999%);

- Target size ≥1.5m×1.8m (matching G8.5 substrate);

- Surface roughness Ra<0.2μm (to avoid poor thin film step coverage).

The large-size silver target developed by Nippon Mining & Metals in Japan, through powder metallurgy + hot isostatic pressing process, achieved 99.9% density and ±2% compositional uniformity, enabling Micro-LED electrode linewidth control within 5μm.

(3) New energy field: The "balance of art" between efficiency and cost

III. Technical barriers and process innovations in target material preparation

1. Purification revolution of high-purity materials

(1) Metal target material purification technology

- Zone melting method Through 10-20 zone melting operations, the purity of copper target materials can be increased from 99.99% to 99.9999% (6N), with iron and nickel impurity content <0.1ppm. Honeywell's 6N copper target uses this technology for copper interconnect layers in processes below 14nm, increasing the current density of the chip to 1×10⁶A/cm².

- Electrorefining method When used for aluminum target purification, high-purity graphite anodes and titanium cathodes are used for electrolysis in an organic electrolyte, reducing sodium and magnesium impurities in aluminum to <1ppm. JX Nippon Mining & Metals' 5N aluminum target uses this process to meet the wiring needs of advanced logic chips.

(2) Ceramic target material synthesis technology

- Sol-gel method When preparing ITO target materials, hydrolysis-polycondensation reaction of indium tin alkoxides can obtain precursor powder with a particle size of <10nm. After sintering at 1400℃, the density reaches 99.5%, which is 3% higher than that of target materials prepared by the traditional solid-state method, and the sputtering rate is increased by 15%.

2. Precision breakthrough in forming process

(1) Powder metallurgy process

- Cold isostatic pressing (CIP) + vacuum sintering When preparing aluminum nitride target materials, molding is performed under a pressure of 200MPa, and then vacuum sintering at 1800℃ can obtain target materials with thermal conductivity >280W/(m・K), meeting the heat dissipation requirements of high-power chips. CoorsTek's aluminum nitride target materials use this process, with thermal conductivity increased by 20% compared to traditional processes.

(2) Hot isostatic pressing (HIP) technology

- Treating the target material at 150MPa argon pressure and 1200℃ can eliminate internal microcracks and pores, increasing the density of tantalum targets from 98% to 99.9%, and the target material utilization rate during sputtering from 30% to 50%. Jiangfeng Electronics' HIP-treated tantalum targets have passed SMIC certification and are used for the deposition of barrier layers in the 14nm process.

3. Microscopic control of surface treatment

IV. Frontier exploration and future trends of target material applications

1. Target material innovation in advanced processes

2. Target Material Breakthroughs in Flexible Electronics

- Sheet resistance < 10Ω/□ (traditional ITO film is 15Ω/□);

- Resistance change rate < 5% when bending radius < 5mm;

- Visible light transmittance > 88%.

3. Three Major Development Directions of Target Material Technology

- Ultimate Purity Development of 7N (99.99999%) grade high-purity target materials for superconducting thin film deposition in quantum computing chips. Shin-Etsu Chemical in Japan has already achieved small-batch production of 7N aluminum targets;

- Intelligent Design Optimizing target material composition through machine learning, such as using Gaussian process regression models to design the copper-indium-gallium ratio of CIGS target materials, resulting in a solar cell efficiency prediction error < 0.3%;

- Green Manufacturing Promoting the hydrothermal synthesis method for preparing ceramic target materials, reducing energy consumption by 40% compared to traditional sintering processes and reducing nitrogen oxide emissions by 50%.

Strategic Value of Target Material Technology

Key words:

Recommend News